Common problems analysis of aro pneumatic diaphragm pump:

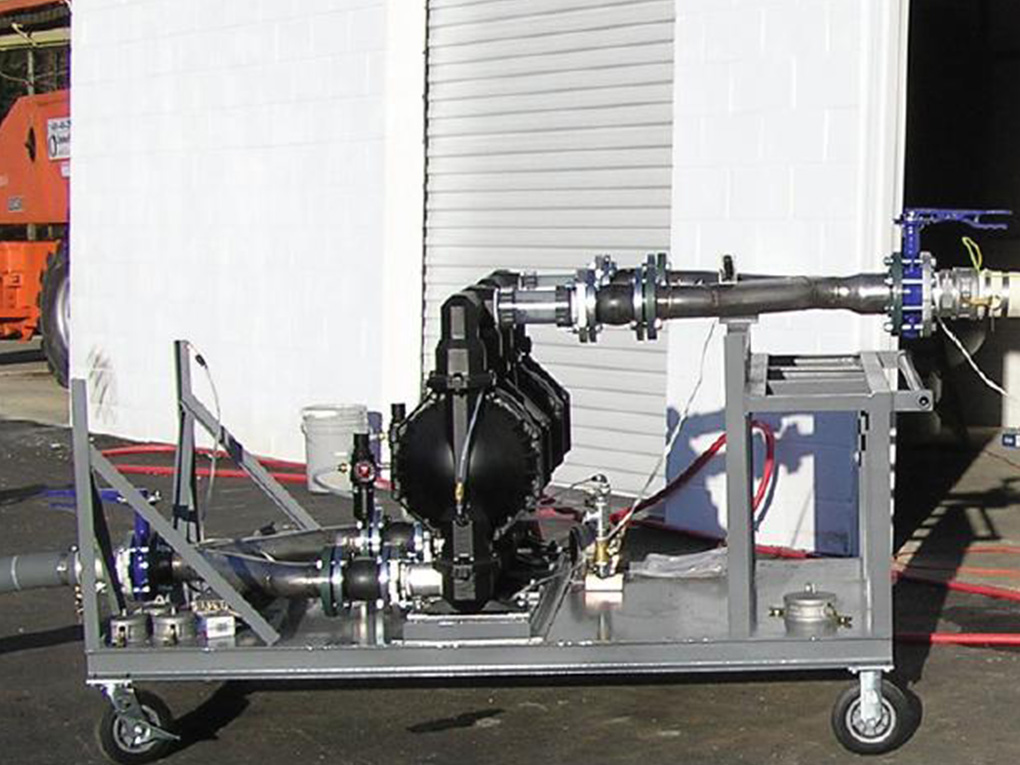

Aro pneumatic diaphragm pump is now more and more widely used and accepted by the public. In many enterprises, such as chemical, spraying, ceramic and other factories, there are many diaphragm pumps. Diaphragm pump can be roughly divided into two categories, one is electric diaphragm pump, one is pneumatic diaphragm pump. Among them, pneumatic diaphragm pump is the most widely used, so here are some maintenance experience of pneumatic diaphragm pump. Hope to help the majority of equipment maintenance personnel, I hope this paper can play a certain role in attracting more valuable opinions. common problem:

1. The pump force is weak and the pump speed becomes slow. This kind of phenomenon has the following several kinds of situations generally, one is the air source pressure reduces. First look at the pressure of the intake pressure gauge, the pressure value of 4 ~ 7kg is normal, and then check the open position of the air source valve. If the air source is opened or closed through the solenoid valve, please check whether the plastic valve piece of the solenoid valve is damaged, so that the plastic valve piece cannot be fully opened. Second, the muffler is blocked, so that the air can not be discharged quickly, resulting in slower pumping speed. Third, there is too much water or impurities in the compressed air. After entering the diaphragm pump valve, plug the air inlet or plug the valve core. The fourth is that the valve core is damaged and leaked by the impact valve cover for a long time. Fifthly, the four sealing rings of the inner shaft of the pump are worn and cross gas appears.

2. Flow reduction. This phenomenon generally has the following several situations, one is the import and export check valve (plastic ball) wear is small. Or there are strips and large particles sticking to the plastic ball. The result is that when the material is sucked out, the material liquid at the outlet is filled, and when the material is discharged, the material liquid is pressed back from the inlet. The second is the long-time tensile deformation of the diaphragm, which leads to the reduction of the material cavity volume. The third one is black. The diaphragm is damaged. When the center axle is driven, it is not in place.

3. The pump doesn't work. There may be several cases of this phenomenon. First, the valve core is seriously worn and stuck. Second, the shaft sleeve is worn. At this time, the copper sleeve should be replaced. Third, the screws on both ends of the central shaft are missing. Fourth, two diaphragms broke. Fifth, the diaphragm pump inverted or flat.

4. There are impurities or oil stains in the materials. This is usually caused by rupture of the diaphragm.

5. Leakage of import and export. Firstly, the screw is not tightened; secondly, the sealing ring is deformed or damaged; thirdly, both ends of the pump shell are not inclined to the holes on the top, resulting in the two discharge ports or feed ports not on the same plane.

Shenzhen great tower Industrial Co., Ltd.is a manufacturer of pneumatic diaphragm pump integrating R & D, production, sales and after-sales service. Its products are widely used in domestic and foreign chemical plants, shipyards, paint plants, water treatment plants, automobile manufacturers and other units. It is a domestic enterprise with higher requirements for the process quality of pneumatic diaphragm pump products, and its technical indicators surpass those of similar domestic products. The main products are aluminum alloy pneumatic diaphragm pump, cast iron pneumatic diaphragm pump, stainless steel pneumatic diaphragm pump, polypropylene pneumatic diaphragm pump, powder pump, high pressure pump, pneumatic diaphragm pump accessories, etc.

Copyright ? 2021 Shenzhen great tower Industrial Co., Ltd. all rights reservedTechnical support粵ICP備2020110751號SITEMAP

Address:402, building 27, Dafa Industrial Zone, Longxi community, Longgang street, Longgang District, Shenzhen City, Guangdong Province

Copyright ? 2021 Shenzhen great tower Industrial Co., Ltd. all rights reserved